|

5

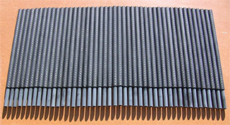

ways we can serve you better than our competition We offer a high quality product on a consistent basis We guarantee that every tube will be within the tolerances given. We don't do spot checking here, every single tube gets measured and visually inspected for defects before it leaves our shop. Single tube minimum on custom tubes 1 tube 30" long, that's it! Wide selection of proprietary tooling We have over 100 mandrel sizes between zero and four inches. If we own it you can use it. No minimum charge for custom tubes The only price of entry for our services is the price of the tubes themselves. $5-20K minimums are not uncommon in our industry. Fair tube pricing We don't compete with Chinese factories but we will offer you a reasonable price with volume discounts for tubes made right here in the states. |

|

TUBE

PRODUCTION CAPABILITIES To request a formal quote please fill in the email form below and click submit. Once we receive your quote we will contact you via email to confirm we have received your request. We will provide you with all relevant cost of the tubes and custom tooling if needed. Most quotes will be returned within 24 hours. Please give us as much information as possible so that we can produce an accurate quote for you. If a field is left blank we will assume that data is not relevant to your project. For questions please email us at sales@carbonfibertubeshop.com |