|

Quite

simply a bonded tube assembly consists of two or more carbon tubes

that can be connected by way of a bonded interior or exterior

ferrule (tube) to create one long tube. Typically one end of the

ferrule is bonded while the other end will accept a slip fit to

the next tube in the assembly. This offers the capabilities of

a long tube with the benefits of being able to break the assembly

down into small sections for ease of transport.

We build most

of our bonded assemblies for customers in the photography field

including professionals and hobbyists. Due to the expense of professional

camera boom systems many individuals find it more economical to

build their own system from off-the-shelf parts. Once you have

selected the pan and tilt system, required boom length, and the

camera you wish to use we will quote and fabricate an assembly

to fit your application. Most of the other components can be found

online and you can have a machinist fabricate the other parts

without a lot of expense.

Click

here

to see how one of our customers, writer and professional photographer

Stefan Sargent (RIP Stefan) built a

complete system and wrote about his experience in the December

2008 DV Magazine. Below you will see pictures and technical specs

for some of the different assemblies we have built in the past.

Email or call

us today to discuss your project.

AUTOMOTIVE BOOMS

Our static booms have been so popular we decided to offer a boom

designed for automotive photographers. The boom featured above

features a combined length of 15ft. This super stiff boom has

an outside diameter that measures 2.00". The fiber orientation

and wall thickness is optimized to resist bouncing which will

improve your shots. This boom will work well with a 5-10 lb. tip

weight. We offer options such as extended 20ft length and a sanded

smooth matte finish. We can supply you with the carbon boom but

all other hardware must be purchase separately. A great source for clamps, cups, and other accessories can be found

here.

The automotive boom images are courtesy of Ken Cravillion of Ken

Cravillion Photography. You can see more of Ken's work on his

blog at:

http://kgcphoto.blogspot.com

The images you see below were taken with our 15ft boom. After

the image is shot the boom itself is edited out. Thank you for

the great pictures Ken!

How well do our carbon fiber automotive

booms work?

Professional photographer Jim Davis shares his experience

using a CFTS camera boom after using an aluminum boom from another

vendor. He wrote, "I've used it on a dirt road mounted to a truck, mounted to

a car doing a slow moving burnout, and it has accidentally come in

contact with a large tree. It has proved itself time and time again.

Light weight, durable, stable, easy to assemble and disassemble, and

easy to transport. It has passed my test and recieved my stamp of

approval. I couldn't be happier with it."

Read the rest of his review

here.

VIDEO BOOM CASE STUDY:

20

ft long video camera boom for Italian TV station

Number of sections:

4 / plus 1 extra

Length of each section (excluding ferrule): 60"

Material: Upgraded Intermediate Modulus Carbon

Outer tube diameter: 2.00" (stock tooling)

Section 1 weight: 675 grams (Double wall thickness the first 4"

to accommodate counter weight)

Section 2 weight: 601 grams (8" inner ferrule bonded half

in half out of one end)

Section

3 weight: 602 grams (8" inner ferrule bonded half in half

out of one end)

Section 4 weight: 532 grams (No ferrule in tip)

Spare section weight: 600 grams

Steel push button pin with detent weight: 18 grams x 5 = 90 grams

Total weight of system not including spare section, including

pins: 2500 grams (5.51 lbs.)

Total horizontal deflection under 5 lb tip weight: 7.5" from

base to tip assuming first section is fixed in place. In operation

there are 3 tube sections (15ft) in front of the tripod or pivot

point. At 50-60 degrees the camera boom will have much less deflection

given the same weight, horizontal positioning shows worst case

deflection. Each section was precision drilled and deburred. All

interior and exterior tube ends were micro contoured for operator

comfort and rapid setup.

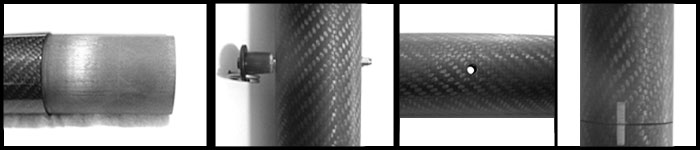

Standard

modulus sanded smooth camera boom

5

sections 49" long including ferrule. Shorter lengths used

to avoid high airport transport fees.

To keep the sections together in down shots we chose these very

precise push button through pins with a detent ball near the end.

We drill holes through the mid-plane of the tube to keep as much

rigidity to the assembly as possible. Boom is designed to be used

with the pins in the horizontal position. Some of our customers

have used velcro to keep the tubes from sliding apart since the

sections are so light weight as shown in the picture below, far

left.

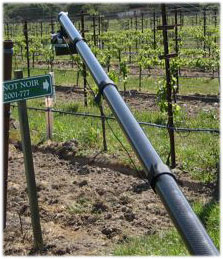

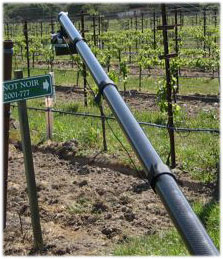

Standard

modulus carbon fiber field boom (vertical use only)

We painted these for the customer to protect from

UV exposure.

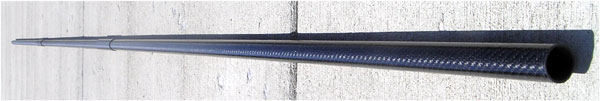

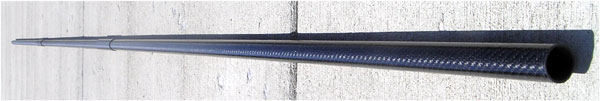

3

pc / 15 foot sport fishing boom with outer bonded ferrules

The customer requested that we use stock tubes

and keep the OD below 1.00" for the main body of this assembly.

At the time we only offered .037" wall thickness in the stock

size below our .995" OD so we elected to use an outer ferrule

for structural reasons while keeping the max 1.00" OD in

mind. We make a great effort to work within the customers budget

and technical requirements.

With each of our bonded assemblies we ensure that everything

fits before leaving our shop. The inner ferrule must be sanded

to a specification that will maintain an adequate bond gap while

at the same time holding a tolerance tight enough that you experience

very little side play on the slip fit side of the ferrule. Each

assembly section is micro contoured on the inside and outside

of each end to make handling comfortable.

We do this to avoid

any chance of a carbon sliver coming off in your hand. This also

aids in faster assembly time. If we drill holes they will be deburred

inside and out prior to cleaning and shipping your assembly. We

believe the little things do matter! We can also assist you with

a quote on collapsible tubing assemblies where each tube fits

into the next which eliminates the need to use of ferrules and

makes storage even more compact. We await your

request!

|